Today’s topic regards minimum weight for balances and is based on information from the U.S. Pharmacopeia (USP), an organization that makes standards to ensure the quality of pharmaceutical products. The following is a summary of the contents of USP Chapter 41 Balances.

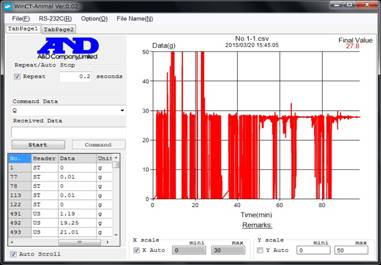

“Unless otherwise stated, when substances must be accurately weighed for analysis, the measurement uncertainty (random or systematic error) of the weighing equipment used must be no larger than 0.10% of the measured value. For measurement uncertainty, repeatability is assessed by weighing one test weight 10 times and is satisfactory if twice the standard deviation of the weighed value, divided by the nominal value of the weight used, does not exceed 0.10%.”

The standard goes on to say that the minimum mass measured by a weighing instrument should be 2000 times the repeatability (defined by standard deviation σ) that is obtained through 10 successive measurements of the same, unchanging mass, such as a standard weight.

The wording of this standard appears to be incredibly difficult to understand at first glance. What it states, however, is simply that, considering 2 sigma (deviation of a 95% confidence interval), measurements carried out with this deviation below 0.10% are considered satisfactory for ordinary weighing.

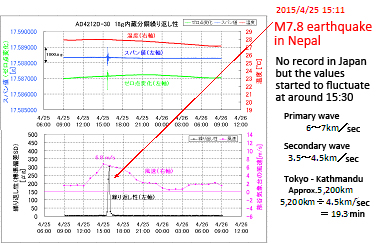

However, is there any meaning to deciding a standard precision requirement for all measurement and weighing occurring in different situations? That is, for measurement and weighing sites, generally the required precision for each site is different. It is readily apparent that the required uncertainty for dealing with gold is vastly different than weighing candy. It is also necessary to consider what is lost and what is gained as a result of single-minded focus on pursuing precision. In particular, microanalysis is an industry that has the some of the strictest requirements for weighing in modern society, requiring minimum weight at the milligram level. For these measurements, a deviation of 0.1% for a weight of, say, 1 mg would require a repeatability of half a microgram (1 mg / 2000 = 0.5 μg). The only type of balance with the capacity to guarantee such minute repeatability is an ultra microbalance. The measurements required by this standard at that infinitesimal scale would dictate the purchase of such an ultra microbalance. Unfortunately, these balances are not only extremely expensive but also incredibly difficult to use.

As I mentioned previously in Development Story 38, maintenance of the weighing environment and proficiency in weighing operations are of utmost importance. Currently, what seems most problematic is the fact that balance manufacturers highlight only the importance of the minimum weight and the standards for it. They then sell balances and afterwards leave the problems concerning errors arising from installation environment and how the balance is operated unsolved. They make no attempt to resolve these problems. In the end all that remains is an abundance of expensive dust-covered paperweights that happen to be called “ultra microbalances”. This lack of support is responsible for the deterioration of trust in weighing device manufacturers.

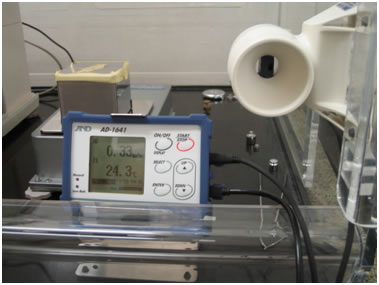

Under these circumstances, figuring out how best to deal with these problems at the places where these balances are actually used has become quite an issue. Although the minimum weight was first defined as the standard deviation times 3000 and now has been revised to 2000 times the standard deviation. This only served to prove the standard was a theory only on paper that failed to consider the work actually being done at the various laboratories. From my experiences abroad and at domestic laboratories, there were very few places that I thought had suitable weighing environments for microbalances, namely some public institutions and balances manufacturers in Europe and research organizations in Japan. In elemental analysis a calibration curve is used on the sample to be measured and always gives a result. However, this requires confirmation of the precision of the device used for this analysis.

In the past, the minimum display of measurement devices including analytical balances was used as a reference value and there was an unspoken rule that measurements were taken from the next most significant digit from the minimum display. The reason for doing this was that balances had many display digits and were subject to many disturbances from operation as well as from the environment which made it difficult to determine stable weights from the minimum display digit. People realized that 10 times the minimum display was required as the determinable display. There was also rule that stated that 1000 times the determinable display would be sufficient to obtain results whose uncertainty is within 0.1%. With a repeatability of 3 micrograms, the 3 sigma value is 10 micrograms allowing for accurate weighing of 10 mg samples. This means that the current minimum weight is nothing more than the standardization of the previous unspoken rule of measurement.

Given all that has been said above, while the idealistic minimum weight standard may be reasonable for general purpose balances or general analytical balances with 0.1 mg minimum displays, it is not appropriate for microbalances. When it is not necessary to confirm 0.1% at the place of analysis, instead of blindly following the standard, a flexible response that takes into account the necessary weighing precision is vital. Using the example of balance repeatability, if the minimum weight is redefined as 1000 times the standard deviation balance users would determine that what really should matter is that weighing precision is suitable to one’s intended purpose without getting caught up in a spec war about microbalance repeatability. Also, given similar expenditures, instead of spending 100% of the purchase cost on the balance itself, there is value to be had in investing in creating a worry-free weighing environment through the proper maintenance of the measurement environment or participation in training that ensures proper weighing techniques.