A&D has developed an air flow logger capable of detecting breezes with speeds below 1m/s. For this development story I have put some material together on the background behind the development the air flow logger and also some market information related to safety cabinets.

A few years ago we developed and started selling the BM series of microbalances capable of microgram measurement. The BM series includes our flagship products, the BM-20 and BM-22, which are currently the only microbalance made in Japan. We have developed products like the BM-252, a world-first device capable of a minimum resolution of 10 μg through the full range of its 250 g capacity, that still remains the only of its type in the world.

When designing the BM series, I traveled around gathering information from laboratories and dealers. At that time, many microbalances found in labs were literally collecting dust. I inquired as to why these microbalances that cost upwards of 2 million yen were being left unused and was told that they are so unstable that they are useless. Meanwhile, I was also reminded of the fact that about 10 years ago a domestic maker began to offer microbalances only to be inundated with complaints and quickly retreat from the market. I think that in the background of all this if Japanese balance manufacturers are going to sell microbalances, it is their responsibility to prevent problems that become potential nuisances for the customer in the end.

As a result of visiting various labs I found that microbalances were often placed in unsuitable areas such as on a central table in the laboratory near areas of frequent foot traffic, directly below the vent from an air conditioning system or in direct sunlight near a window. This led me to decide that when selling a microbalance, it was essential to measure the temperature, humidity, atmospheric pressure, vibration and wind speed to show that the location where the balance was to be installed was appropriate.

After some contemplation I realized it was possible to evaluate the environment by monitoring the measurement values of a balance over a long time as balances themselves are sensitive to environment factors. Going one step further we determined that by simultaneously measuring the other environment factors, the source of weighing instability could be ascertained. In order to do just this, in development we came up with a method of obtaining repeatability. This method worked by periodically raising and lowering the internal weight, using the zero and measurement value to determine the span value repeatedly and finally using these span values to calculate the repeatability. We also found it is essential to measure environmental factors contributing to error (temperature, humidity, atmospheric pressure, vibration and wind speed).

This method eventually became A&D’s measurement environment evaluation tool, “A&D-MEET”, which entered the market when the BM series was first sold. However, at A&D there were some issues with using MEET. This was because MEET would incur labor costs that we were unsure of how to consider appropriately. Sales thought the process was too high-maintenance as it requires 1) setup of the balance and running MEET, 2) a return trip to gather the data and 3) another return trip to explain the results. They claimed this process was ineffective for business.

I insisted that as a service fee for using MEET around 100,000 yen should be the established price. I also added that repeatedly visiting the customer could lead to future business opportunities. However, the main reaction I received was that A&D was a company that sold physical items and had no business gambling on services and also that no customer would spend 100,000 yen on an intangible thing such as running MEET. This lengthy debate within the company ended in futility as in the end the price of things is determined by the people who buy them.

Four years has passed since MEET was proposed and A&D’s microbalances are reliably sold by sale representatives with sales continuing to increase every year. From the perspective of the researcher when buying an expensive microbalance the biggest risk is not being able to use the device. Therefore it is easy to conclude 100,000 yen to be a reasonable price for a tool that can avoid or reduce such a risk. Additionally, even if they do not ask for MEET when the balance is installed researchers will feel a sense of safety more than anything else when we explain that we are prepared to deal with any measurement troubles beforehand. Moreover, when beginning to sell microbalances we also began sales of independently designed breeze breaks as well as anti-vibration platforms and balance tables as tools to improve the measuring environment to support the microbalance market.

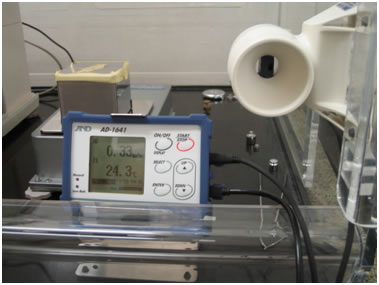

Now back to the main topic, aside from evaluating the environment where an analytical balance is used, the measurement of breezes in labs can be used in the following cases: 1) Measurement and recording of the wind speed at the entrance to a fume hood or balance enclosure, 2) measurement and recording of the holding environment for animals and plants, 3) measurement and recording of the air flow in a cleanroom or laminar flow cabinet as well as the measurement and recording of transport and usage environment of precision devices. When the BM series first came on sale, there was no device in the world that could simultaneously measure and record environmental factors that affect balances such as temperature, humidity, atmospheric pressure, vibration and wind speed. And the addition of the capability to measure low-velocity breezes has culminated in the AD-1641 Air Flow Logger. The AD-1641 can be used to simultaneously record up to 10000 data sets from 6 different measurements, including environmental factors (temperature, humidity, atmospheric pressure, vibration, and wind speed) affecting places from laboratories to production facilities, and measured weight data.

Fig. 1 below shows AD-1641 placed at the opening of an AD-1673 balance enclosure.

I believe that for instance if the AD-1641 is used for the required air flow measurement of all types of safety cabinets, it will serve effectively as an environment recording tool and guarantee the safety and security of researchers working on analysis and materials development as well as producers of materials.

I have experienced firsthand the difficulty of selling world-first products from Japan and yet, as long as I have time, I will continue to strive to design and sell successful products that not only add value but also express creativity.